1KW Stainless Steel Aluminum Handheld Fiber Laser Welder

| Category | Auto Laser Welding Machine |

| Model No. | BE-WF1000M |

| Views | 56300 |

| Rating | ★★★★★4.9/5 Based on 1000 Votes |

| Price Range | US$4199-US$7999/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 5-7 Days |

| Shipping | Air/Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Fiber laser welding machine adopts the latest advanced fiber lasers and equipped with wobble handheld welding gun to realize handheld welding. It has the advantages of simple operation, high accuracy welds, fast welding speed and no consumables. It can weld thin stainless steel plates, iron plates, galvanized plates and other metal materials, and can perfectly replace traditional argon arc welding, electric welding and other processes. The hand-held fiber laser welding machine can be widely used in complex and irregular welding processes in cabinets, kitchens, stairs, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel homes and other industries.

The working mode of the hand-held optical fiber laser welding machine is hand-held welding, flexible and convenient, and the welding distance is longer.

Replacing the fixed optical path with a hand-held welding gun, the handheld optical fiber laser welding machine is mainly used for laser welding of long-distance and large work pieces. During welding, the heat affected area is small, which will not cause deformation, blackening, and pores on the back.

Good Features

◆ Wide Welding Range

The handheld welding head is equipped with 10m original optical fiber, which overcomes the limitation of workbench space and can weld outdoors and remotely.

◆ Convenient and Flexible Use

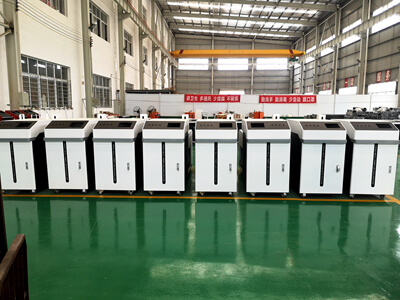

Handheld laser welding is equipped with wheels, which is flexible to move and can adjust the direction at any time, and does not need fixed stations. It is free and flexible, suitable for various working occasion.

◆ A variety of welding methods

It can realize welding at any angle: stack welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc. it can weld work pieces with various complex welds and irregular shapes of larger work pieces. Welding at any angle can be realized. In addition, it can also complete cleaning and cutting. Welding. Cleaning and cutting can be switched freely, just replacing the welding copper nozzle with the cutting copper nozzle, which is very convenient.

◆ Good Welding Effect

Handheld laser welding is hot melt welding. Compared with traditional welding, laser welding has higher energy density and can achieve better welding effect. The welding area has small heat effect, is not easy to deform, blacken and no pores on the back. It can do deep welding, because full melting is firm and reliable, and the weld strength reaches or even exceeds the base metal itself, which cannot be finished by ordinary welding machines.

◆ No Need Polishing

For traditional welding, it need to be polished to ensure smoothness. Hand held laser welding is continuous welding, smooth without fish scales, beautiful without scars, and no after-grinding process.

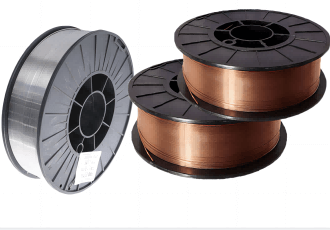

◆ No Consumables

The welding can be easily completed, and no consumables and almost free of maintenance

◆ Multiple Safety Alarms

The switch is only effective when the welding tip touches the metal. The light is automatically locked when the work piece is removed, and the switch is equipped with body temperature sensing. High safety, ensuring the safety of operators during work.

◆ Labor Cost Saving

Compared with arc welding, the processing cost can be reduced 30%. The operation is simple and easy to learn, and the operator’s technical threshold is not high. Ordinary workers can weld after short training, which can easily achieve high-quality welding effects.

Parts Introduction

Whole Machine Structure

- Adopting industrial integrated and European standard design

- Compact and beautiful structure, good beam mode, concentrated energy, stable performance, reliable use, fast welding speed, wide range of suitable welding, long service life etc.

- E,T,G,M different options.

Fiber Laser Source

- China’s best No.1 continuous fiber laser source, with powerful laser beam and enable continuous welding, lifetime over 10 years, no consumables and free of maintenance.

- Raycus, Max, JPT, BWT, Reci different brands fiber laser source for options.

Adopt Famous Brand Fiber Transmission

- Equipped with Japan imported fiber cable, fast speed, stable beam transmission, lest consumption and most powerful.

- Standard 10m(optional 15m and 20m), which is preferred for long distance welding.

Controlling Button

- Separate press buttons for normal operation(Emergency, Key Switch, Laser Button and Power Button) which bring much convenience.

- Easy to operate, and eliminate the risks of errors.

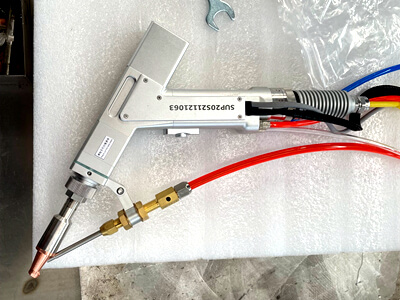

G Design Swing Welding Gun

- Weight: 0.8kg, Industrial and Technology

- Adjustable Laser Beam Size: 0.5-5mm

- Language: Chinese, Chinese, English, Russian, Vietnamese, Korea

- 6 Wobble Modes(spot, line, double circle, triangle, double triangle)

- Double Swing Motors

S Design Swing Welding Gun

- Multifunctional 3 in 1(Auto Welding+Cutting+Cleaning)

- Weight: 0.8kg, Light and Powerful

- Adjusted Laser Beam 0.5-6mm

- Language: Chinese, English, Korean, Russian, Japanese, French, German, Latin, Traditional Chinese, Italian, Spanish, Romanian, Polish

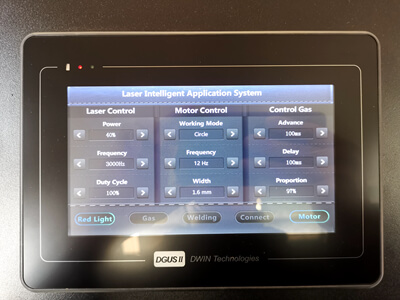

Controlling System

- In-built Software& LCD Touch Screen Controller, high sensitivity, support Chinese, English, Russian, Spanish, Korean etc.

- User-friendly Interface, simple, truly reflects what you see is what you get.

Industrial Water Cooling System

- Installed with top China brand Hanli or S&A constant temperature industrial water cooling system which can adjust the temperature automatically

- Integrated design which help client save much space and shipping fee

- Inner water chiller we use 1.5P water chiller, max water flow can reach 3.3L/minute

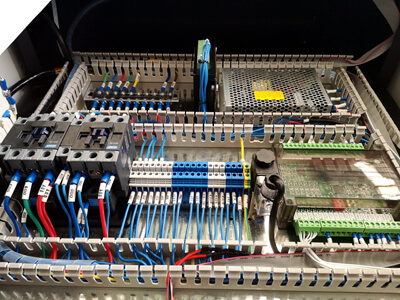

European Standard Electric Parts

- The electric control parts with precise design, integrated circuit board making electrical board in modularization and clear layout which can define classification easily.

- Separated strong and weak current, no interference and stable.

Application

It is widely used in kitchen and bathroom industry, household appliance industry, advertising industry, mold industry, stainless steel door and window industry, handicraft industry, household goods industry, furniture industry, auto parts industry etc.

Optional Items

| Model | BE-WF1000M |

| Laser Running Mode | Continuous/Modulate |

| Beam Quality | M2<1.2 |

| Power | 1000W 1500W 2000W 3000W |

| Line Width | <5nm |

| Laser Device | IPG/Raycus/Max/BWT/CAS Laser |

| Power Consumption | 6kw |

| Spot Size | 0.1-5mm |

| Pulse Width | 0.1-20ms |

| Welding Depth | 0.5-3mm |

| Welding Connector | QBH |

| Fiber Cable Length | 10m (Optional: 15m) |

| Laser Wavelength | 1070nm |

| Position | Red Pointer |

| Continuous Working | 24 hours |

| Cooling System | Industrial Constant Chiller System |

| Working Temperature | 15-35℃ |

| Input Voltage | AC220V±10%,50HZ/60HZ |

| 1000w Fiber Handheld Maximum Welding Depth | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | |||||

| Iron | ● | ● | ● | ● | ● | |||

| Mild Steel | ● | ● | ● | ● | ● | |||

| Aluminum | ● | ● | ||||||

| Brass | ● | ● | ||||||

| 1000w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | |||||

| Galvanized Sheet | ● | ● | ||||||

| Iron | ● | ● | ● | |||||

| Mild Steel | ● | ● | ● | |||||

| Aluminum | ● | |||||||

| Brass | ● | |||||||

| 1500w Fiber Handheld Maximum Welding Depth | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ● | |||

| Galvanized Sheet | ● | ● | ● | ● | ● | |||

| Iron | ● | ● | ● | ● | ● | |||

| Mild Steel | ● | ● | ● | ● | ● | |||

| Aluminum | ● | ● | ● | |||||

| Brass | ● | ● | ||||||

| 1500w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | |||||

| Iron | ● | ● | ● | ● | ||||

| Mild Steel | ● | ● | ● | ● | ||||

| Aluminum | ● | ● | ||||||

| Brass | ● | ● | ||||||

| 2000w Fiber Handheld Maximum Welding Depth | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ● | ● | ||

| Galvanized Sheet | ● | ● | ● | ● | ● | |||

| Iron | ● | ● | ● | ● | ● | ● | ||

| Mild Steel | ● | ● | ● | ● | ● | ● | ||

| Aluminum | ● | ● | ● | ● | ||||

| Brass | ● | ● | ||||||

| 2000w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | ● | ||||

| Iron | ● | ● | ● | ● | ||||

| Mild Steel | ● | ● | ● | ● | ||||

| Aluminum | ● | ● | ● | |||||

| Brass | ● | ● | ||||||

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-WF1000M | 1.2m×0.73m×1.27m, 1.13CBM | 260KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

Vova Boyko

★★★★★Post a review on Aug 21, 2022 From Russia

Perfect welding seam, and much much better than traditional welding machine. Welding smoothly and firmly. We are building new factory and will add more units if working well.

-

Jose Hernandez

★★★★★Post a review on Aug 21, 2022 From US

Machine performs well. Laser welding gun very light and user-friendly. Our workers are quite satisfied with the machine. Thank you BST Laser!

-

Stephanie Lunder

★★★★★Post a review on Aug 21, 2022 From Canada

Very professional. This machine can do welding, cleaning and cutting. It really beyond our expectation. No need after polishing and sanding.The machine so amazing!

-

Pramod Mahato

★★★★★Post a review on Aug 21, 2022 From Australia

We use the machine to weld stainless steel. The welding speed very very fast. It can save 3 welders’ job and save us huge cost! Thanks for the new laser technology!

-

Ana Garcia

★★★★★Post a review on Aug 21, 2022 From Spain

We do a lot of study before purchasing. There are different choice on market with different offers. Never use such machine before, so at the beginning we are a little bit worried, but finally found out BST is very professional and provide excellent after-sale service. Be rest assured to buy!

-

Mohammed Makki

★★★★★Post a review on Aug 21, 2022 From UAE

It is definitely faster than argon welding. The welding seam is exquisite and bear more pressure. Workers feel relaxed!

-

choi yunje

★★★★★Post a review on Aug 21, 2022 From Korea

Machine is same as seller’s description. Easy to use, no need much skills. Workers can operate the machine after 30 minutes training. It is the right machine we require!