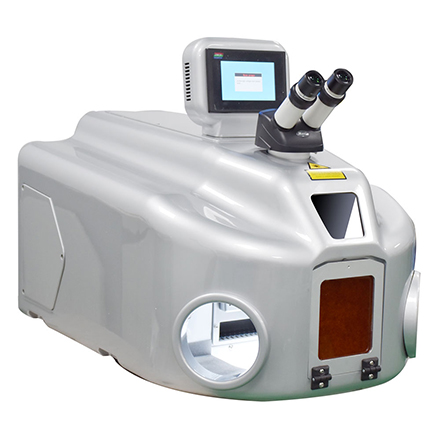

Mini Portable Gold Silver Welding 200W Jewelry Repair Machine

| Category | Auto Laser Welding Machine |

| Model No. | BE-W200 |

| Views | 38070 |

| Rating | ★★★★★4.8/5 Based on 500 Votes |

| Price Range | US$3800-US$4800/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time | 7-15 Days |

| Shipping | Air/Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Jewelry repair machine is also called laser spot welding machine, gold and silver jewelry laser welding machine, and laser repair welding machine. It is specially used for gold silver jewelry, electronic components repair, spot welding, welding inlay etc. The welding is firm, beautiful, non-deformed, simple to operate and easy to use.

Jewelry repair machine is mainly used to repair jewelry holes and do spot welding on gold and silver jewelry. Laser spot welding is an important laser processing technology. The spot welding process relates to heat conduction type, by which, laser radiation heats the surface of the work piece, and the surface heat is guided to internal diffusion through heat conduction. By setting up the width, energy, peak power, repetition frequency and other parameters of the laser pulse, the work piece is melted to form a specific molten pool. Due to its unique advantages, laser spot welding has been successfully applied to gold silver jewelry processing and welding of micro and small parts.

Good Features

◆ Mini portable compact size with European design, easy for moving.

◆ Energy, pulse width, frequency and spot size can be adjusted in a large range to achieve a variety of welding effects. The parameters are adjusted by the control stick in the closed cavity, which is humane and efficient.

◆ UK imported ceramic laser cavity, which is corrosion-resistant, high-temperature resistant, high photoelectric conversion efficiency, long life of condenser cavity (8-10 years), xenon lamp life of more than 8 million times.

◆ Adopting advanced automatic shading system to eliminate eye irritation during working hours.

◆ 24-hour continuous working capacity, stable working performance, and maintenance free within 10,000 hours.

◆ Humanized design, ergonomic and long-time work without fatigue.

◆ Fast speed, high efficiency, welding deep, small deformation, small heat affected zone, high welding quality, no pollution of welding points, high efficiency and environmental protection.

Parts Introduction

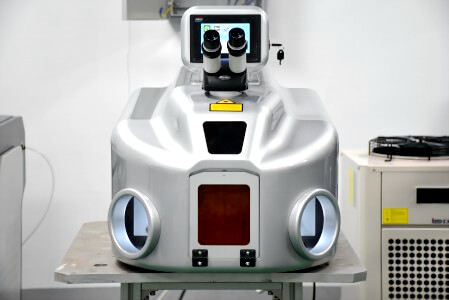

Humanized Design

- It adopts latest European portable mini design, scientific streamlined mechanical structure.

- 3D printing machine casing body, anti-static, anti-rust, easy moving and saving space.

Observation Microscope

- It adopts China top quality high-precision microscope(10X), which enable accurate positioning and welding process.

- Operator can observe the welding process clearly, which ensure the welding high precision.

Controlling Screen

- It adopts built-in controlling system with touch screen, which ensure high sensitivity and enable convenient parameters setup.

- Users can set up different parameters (current, frequency, pulse…) according to different materials. Parameters can storage.

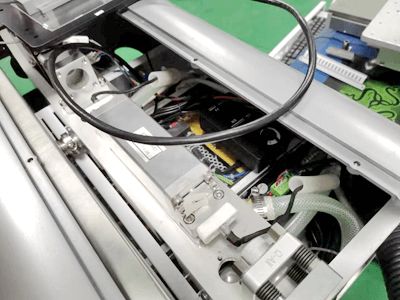

Laser Optical Path

- It adopts UK imported Morgan brand optical cavity, which protect the laser source and extend the lifespan.

- It adopts Beijing famous brand crystal rod, which designed by China 11th Scientific Research Institute, powerful and not easily damaged.

Crystal Rod

- Beijing famous brand 7*145 crystal rod, which designed by China 11thScientific Research Institute

- Intensive Energy and Not Easily Damaged

- Maximum Power Reach 230W

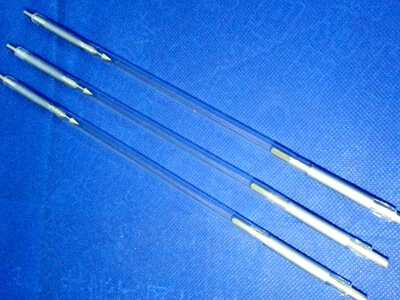

Laser Xenon Lamp

- It adopts China top brand original Xenon lamps.

- Lifetime: 8,000,000 times,for example,work 8 hours per day,one lamp can use for 6-12 months.

- Xenon lamp is the power source of laser, when xenon lamp finished, just need change a new one.

Joystick

- When users do welding job, they can also move the joystick to adjust the cursor position to set the parameters.

- Emergency top/joystick/brightness

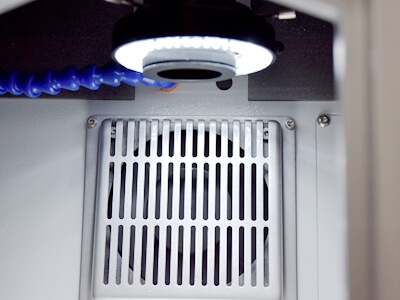

LED Lights

- Operator can adjust the led lights brightness considering eye comfort.

- High brightness, long lifespan, energy-saving and installation conveniently.

Gas Pipe

- To ensure clean welding, it needs blow Argon gas to protect the welding surface.

- Adjust the gas blowing direction according to the welding position.

Working Table

- It equips with big inner working space, which enable human hands’ flexible angle.

- It is convenient to place tools or fixtures inside.

Exhaust Fan

- Machine equips with both water cooling and air cooling. Double assurance for cooling.

- There are 3 big high speed exhaust fan on the back side, which helps cooling.

- There are water cooling system inside the machine.

Voltage

- Machine voltage is 220v 50hz

- Power input/gas input/foot pedal

Application

Gold, silver, platinum, copper, titanium, stainless steel and other metal materials, rings, earrings, bracelets, necklaces, tie clips, cufflinks and other jewelry, metal jewelry welding. As well as the welding of small hardware products in precision parts, electronic components, micro motors and other industries.

| Model | BE-W200D |

| Power | Peak 200w |

| Wavelength | 1064nm |

| Power Consumption | 3KW |

| Pulse Energy | 100J |

| Laser Focus | 110mm |

| Pulse Frequency | ≤0.1-20Hz |

| Pulse Width | ≤15ms |

| Protection Gas | Single |

| Voltage | 220V/110V |

| Observation System | Microscope 10X or CCD camera |

| Cooling | Inner Water Cooled |

| Controls | Touch Screen or Joystick |

| Language | Chinese/English |

| Protective Gas | Argon |

| Dimension | 850*550*650mm |

| Net Weight | 85kgs |

| Package Size | 940*650*750mm |

| Package Weight | 100kgs |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W200 | 0.94M×0.65M×0.75M, 0.46CBM | 100KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

Carlos enrique mejia boer

★★★★★Post a review on Aug 21, 2022 From Mexico

The welding seam is very beautiful, and it can repair different damage. Very useful!

-

Alexandr Perkanuk

★★★★★Post a review on Aug 21, 2022 From Russian Federation

Welded perfectly. It can repair different jewelries. Everything runs smoothly.

-

talleresvisocar limens

★★★★★Post a review on Aug 21, 2022 From Spain

The effect is very satisfactory, and welding seam very thin.

-

M van Steen

★★★★★Post a review on Aug 21, 2022 From Netherlands

It is very powerful. Thanks to the staff for patiently explaining and looking forward to the follow-up use.

-

Danilo Jovetta

★★★★★Post a review on Aug 21, 2022 From Brazil

For gold and silver jewelry processing, I heard BST from one friend. Laser welding is quite suitable for processing jewelry, and very economic price.