Flat Alumiunm Stainless Steel Letter Bending Machine

| Category: | Channel Letter Bending Machine |

| Model No.: | BEL-M120 |

| Views: | 7000 |

| Rating: | ★★★★★5/5 Based on 1000 Votes |

| Price Range: | US$4000 – US$6000/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time: | 10-15 Days |

| Shipping: | Sea/Train/Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

CNC Channel Letter Bending Machine M120 adopt servo motor and ball screw transmission, mechanism arm clamping feeding structure. With large feeding torque, high precision and fast speed. The mechanism arm clamping adopts the emery coating process to prevent slipping and improve the feeding accuracy effectively. The M120 model also has a unique material reminding function to ensure that the material is not wasted through the slotting system.

Machine Feature:

◆ Mechanical arm alternatively feeding structure ensure fast feeding speed&no any deformation on materials.

◆ Ball screw and servo motor transmission can easily hold flat aluminum from 1.5 mm stainless steel to 0.6 mm flat aluminum.

◆ Materials bending height:20-120mm

◆ Bending Thickness: stainless steel 0.3—2mm, galvanized sheet 0.4—1.2mm, flat aluminum 0.6—1.5mm.

◆ Forming alloy knives eliminates the trouble of grinding and longer lifetime.

◆ The telescopic shaft bending mechanism can achieve small degree arc bending at the most extent.

◆ Supporting various vector file format like AI, PLT, DXF, NC, etc

Parts Introduction

Indicator and Function Press Button

- Clear button for each normal function, making whole operation easy.

- Easy to change between bending stainless steel and aluminum materials by pressing switch button

Closed loop feed feedback system

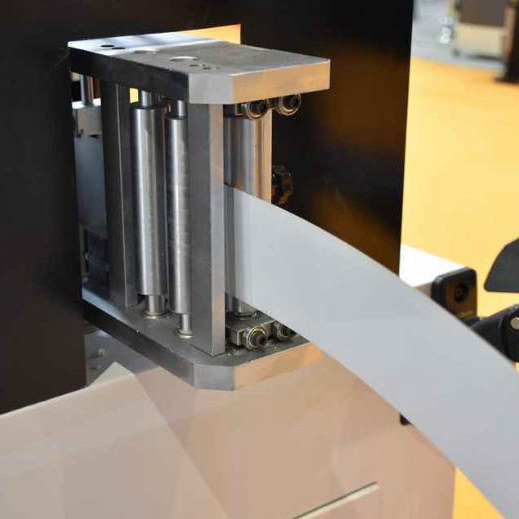

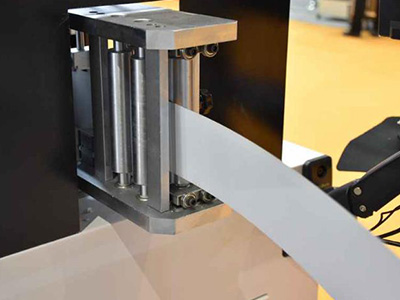

The alternating clamping feeding structure with large torque, high precision and high speed transmission performance, it is driven with double screw rods and positioning nuts and controlled by servo motor to ensure real material feeding accuracy to ±0.1mm. it solves problems of slipping and independent of roller pressure feeding type.

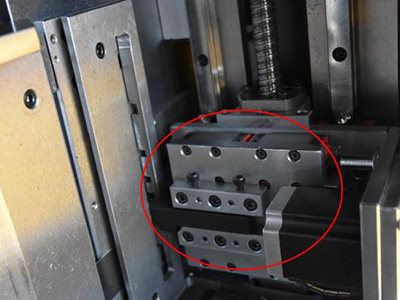

Double-axis Alternating Telescopic Bending Structure

Which can avoid the interference phenomenon of the bending axis to the greatest extent, the small arc and the small angle forming degree are very high.

Ball Screw Drive Alternate Feeding Structure

- The double-axis alternating telescopic bending mechanism automatically replaces the bending axis according to the inner and outer arc changes of the figure, which can avoid the interference phenomenon of the bending axis to the greatest extent.

- Small arc and the angle forming degree are very high,the control software has built-in multi-point slotting function.It can effectively thin the materials thickness and easy bending.

Standardized wiring and IO Integrated PCB

- The electrical control part is with precise design, integrated circuit board making the electrical part in modularization

- Clear layout which can defined classification easily. the circuit part is separate with strong and weak electricity,no interference and more stable.

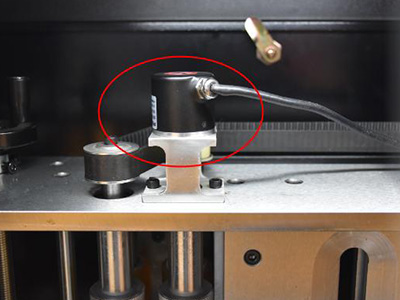

Korea Imported Plane Cutter for Stainless steel

- Adopting Korea imported hard alloy knives ,no need grinding

- The round tip structure makes the toughness stronger when the material is bent.

Ball Screw Transmission and Servo Motor Control

- Ensure the strong torque, high precision and fast speed.

- Can easily hold flat aluminum from 1.5 mm stainless steel to 0.6 mm flat aluminum

Application

The M120 bending machine is driven by mechanism arm clamping and servo motor.

It can easily hold flat aluminum from 1.5 mm stainless steel to 0.6 mm flat aluminum. Forming alloy knives eliminates the trouble of grinding. The telescopic shaft bending mechanism can achieve small degree arc bending at the most extent.

Optional Items

| Category | Feeding system | Rolling continuous feeding structure(Closed loop self-test system) |

| Slotting system | Ball Screw Transmission, Korean KORLOY Slotting Knife/Pneumatic lifting rotary milling cutter structure (Reversible swing knife) | |

| Bending system | Two-axis linkage arc system/ Two-axis linkage copper shaft roller extrusion system(Non-scratch material) | |

| Driving motor | Servo motor 2 set; stepper motor 3 set | |

| Weight | 340kg | |

| Dimensions | Body: L1500mm×W850mm×H1550mm; Feeding Table: L500mm×W500mm×H1100mm | |

Performance |

Material category | Aluminum profile, stainless steel, galvanized sheet flat aluminum (20—150mm) |

| Material thickness | Stainless steel 0.3—0.8mm Galvanized sheet 0.4—1mm Aluminum profile 0.6—1.5mm |

|

| Support format | AI PLT DXF NC | |

| Feeding accuracy | Length±0.1mm; Radius>10mm | |

Sfotware |

Control card | ADTECH/Leetro Four-axis motion control card |

| Software system | Autodrive/CBS4 auto bending system | |

| Input voltage | 220V 50Hz 3Kw | |

| Air pressure | 0.6-0.8Mpa |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-S150 | 210cm×81cm×165cm,2.807CBM | 350KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craft case. |

-

Hossein Azimi

★★★★★Post a review on Aug 21, 2022 From UK

The machine is very strongly mechanically and features very good, easy software and performance is very good.

-

Muhammad Tayyab

★★★★★Post a review on Aug 21, 2022 From UK

Very powerful machine, it has brough many potential clients to my business, recommends to others who want to enter sign field.

-

Ermal Alushi

★★★★★Post a review on Aug 21, 2022 From Italy

The trim cap channel letter letter bender machine BEL-A200 is working fine, for now we do not have any technical support.

-

Josef Helmlinger

★★★★★Post a review on Aug 21, 2022 From Chile

The machine works well. I will introduce to friends to buy.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From Spain

Your letter bending machine is very fine and I am so happy and thankful to u and ur company.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From France

Also let you know, we have been using the machine very well, because of pandemic we haven’t been able to us it that much, but in the little we have made really good letters with it!

-

Ernesto Reyes

★★★★★Post a review on Aug 21, 2022 From USA

High quality machine. I want to thank supplier for her support and enormous help during purchase.