Flatbed Single Table Fiber Metal Laser Cutting Machine

| Category: | Fiber Metal Laser Cutting Machine |

| Model No.: | BE-FM-3015S |

| Views: | 5800 |

| Rating: | ★★★★★5 /5 Based on 3500 Votes |

| Price Range: | US$12,000 – US$35,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer |

| Leading Time: | 30-45 Days |

| Shipping: | Sea Shipment |

| Warranty Period: | 36 Months for Machine and 24 Months for Fiber Laser Device with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Fiber Metal Laser Cutting System have developed into one of the most popular and affordable high precise metal processing equipment. The flatbed sheet metal laser cutting machine with single table is an ideal entry level metal laser cutter without any high purchase cost or training cost. With easy operation and simple maintenance, the flatbed fiber laser cutting machine provide users powerful cutting ability and efficiency. Therefore, it is a good choice for users to have an economical processing.

STANDARD COMPONENTS

◆ CYPCUT®FSCUT2000 CNC Control System

◆ Fuji®High Dynamic EtherCAT servo drive

◆ BSTLASER®Dynamic System 4.0:1.5g Acceleration

◆ BSTLASER@Fast Piercing 2.0:Ultra Performation

◆ Automatic Table Exchanger 3015 (Optional 4015,4020,1560,2060)

◆ Smoke Extraction Fan System

◆ Fiber Laser Source Raycus 1000w 1500w 2000w 3000w

◆ Class IV safety system and CE marking

◆ CYPCUT@Embedded Pcs:Industrial PCs with direct ly integrated I/O level

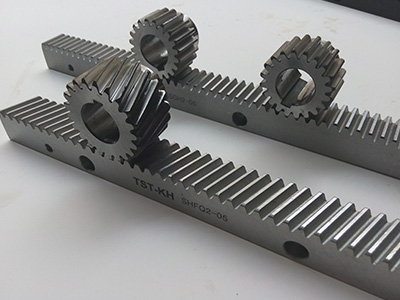

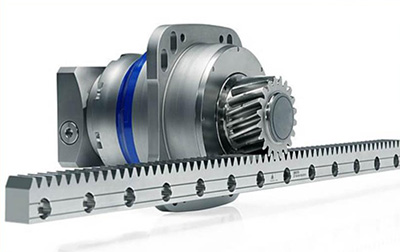

◆ Hiwin@High performance and high accuracy rack and pinion system

Metal Cutting Capacity

| Laser Power | 1000W | 1500W | 2000W | 3000W | |

| Nominal power | kw | 1 | 1.5 | 2 | 3 |

| Power requirement | kw | 7 | 7 | 8 | 12 |

| Wavelength | nm | 1074 | 1074 | 1074 | 1074 |

| Cutting capacity | |||||

| Carbon steel | mm | 10 | 16 | 20 | 22 |

| Stainless steel | mm | 5 | 6 | 8 | 10 |

| Aluminum Alloys | mm | 3 | 4 | 6 | 8 |

| Brass | mm | 2 | 2.5 | 5 | 6 |

Machine Feature:

◆ The machinery structure adopts an industrial-use grade heavy-loading base design. All components are 100% assured top superior quality standard, original and genuine.

◆ The transmission system adopts a bridge gantry type middle drive structure, double rack servo drive, and high inertia high torque Japan Yaskawa servo motors.

◆ Taiwan high precision rack and reducer’s max acceleration can reach 1.5G, which ensures high speed and high precision operation.

◆ The overall machine body is built on a thicker cast iron structure and an entire cast aluminum gantry.

◆ The strong base has been processed through milling and secondary annealing to effectively eliminate stress.

◆ It adopts world famous superior quality fiber laser generator and high precision USA imported cutting head with dynamic following and focusing.

◆ Fiber laser generator lifespan over 10 years, almost no consumables and free of maintenance.

◆ High performance laser cutting control system with full closed loop control.

◆ Z-axis precision industrial linear module system.

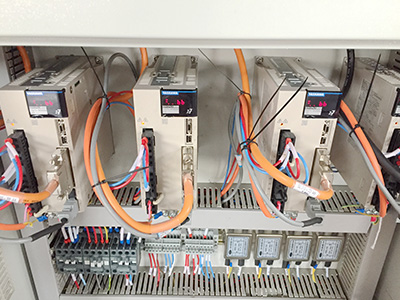

◆ Independent control cabinet, industrial machine tool foot and thick towline cable.

◆ European electrical standard design and France brand Electric components.

◆ Professional laser cutting software with graphic layout and sharp corner smoothing function, which can realize high-speed penetration.

Parts Introduction

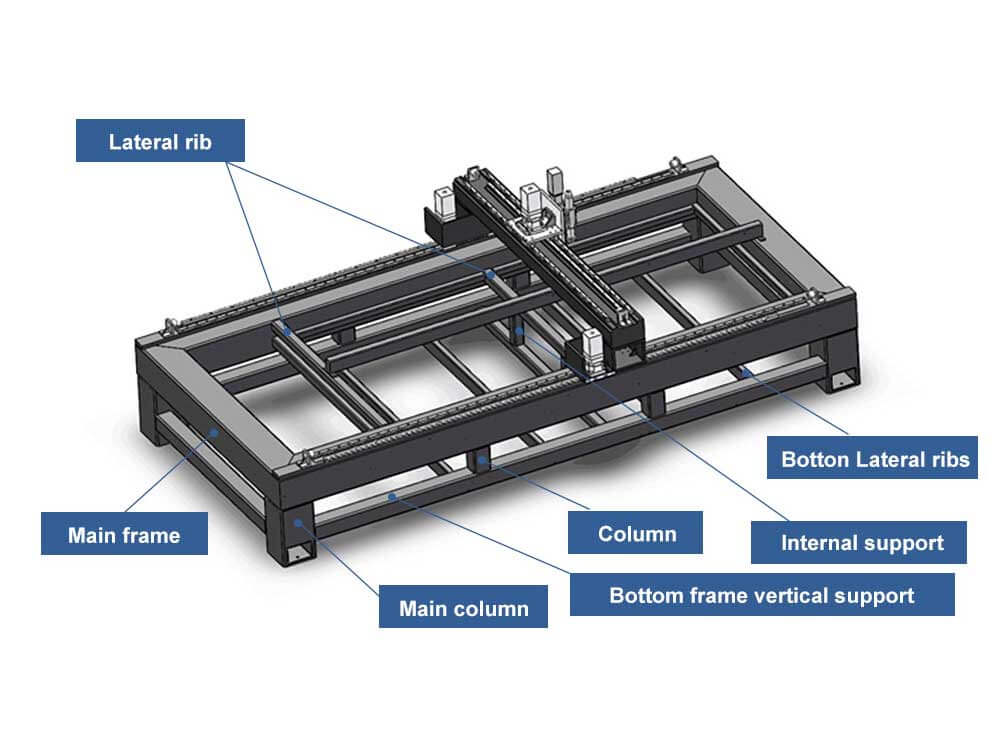

Machine Body

- Adopting heavy-duty square tube welding structure with thickness of 8mm and reasonable structural design.

- CNC machining, milling three times.

- The first pass is roughing and leveling, the second pass is fine milling and the third pass is finish milling.

- The machine body can ensure stability and non-deformation for 50 years, and has the characteristics of stable structure, good rigidity and high dynamic response. The integrated cast aluminum gantry ensures high speed and high balance performance.

Cast Aluminum Beam

The integrated cast aluminum gantry ensures high speed and high balance performance, with light weight, good dynamic response, faster acceleration, better comprehensive cutting effect.

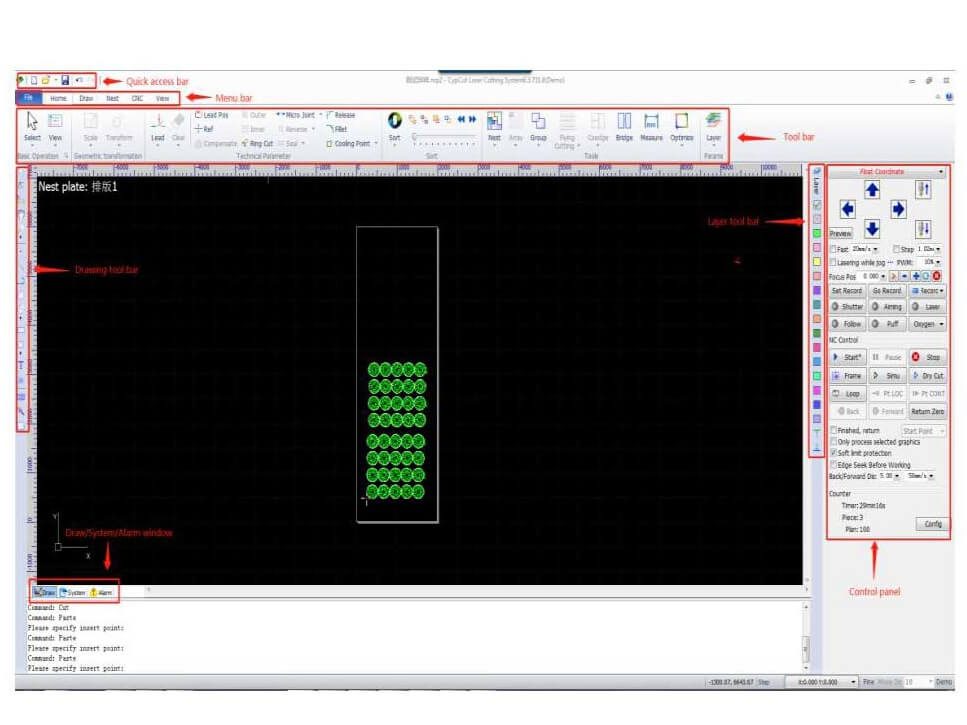

FSCUT2000S Cypcut Control System

FSCUT2000S medium power laser cutting system is a full-solution open-loop control system specially designed for the sheet metal fabrication industry, with features of easy to install and adjust, excellent performance and fully integrated solutions, it is the upgrade version from FSCUT2000C.

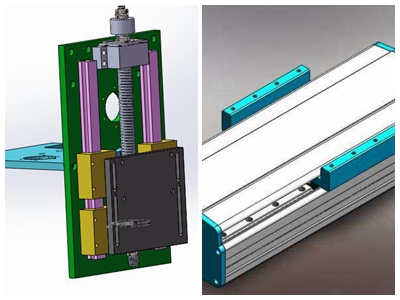

Z Axis Transmission

Z-axis adopts high-precision industrial linear module slide table and advanced servo traveling system, ensuring high precision, longer lifetime

Transmission System

- Famous Brand HIWIN linear guide and BYYC grinding gear rack

- Max traveling speed reach 80m/min and max acceleration reach 1.5G

Auto Foucing Laser Cutting Head-Raytools Swiss

- Modular design with easy maintenance.

Dual water cooling circuits. - Auto focus to reduce human intervention and improve piercing and cutting efficiency.

- 3 Cover glasses (top, middle and bottom) to protect collimation & focus lens.

IP65 class dustproof, patented cover glass cover plate. - Accuracy≤50um

Collimation Side (Top)Φ24.9*1.5mm - Focusing Side(Bottom/Middle)Φ27.9*4.1mm

Servo Motors

- Original Japan Yaskawa Servo Motor system(Σ-7series)

- X/Y/Z axis all adopt Japan Yaskawa motor. Y Axis is equipped with dual driverIt can realize high-speed and high-precision transmission.

Reducer

- Japan Simbo reducer

- Flange output,

- Accuracy and stability life are more than 10 of the shaft output

- Grade 3 accuracy

Cooling System

- Top China Brand S&A CWFL series with a variety of alarm protection functions.

- It has two working modes of constant temperature and intelligent temperature regulation.

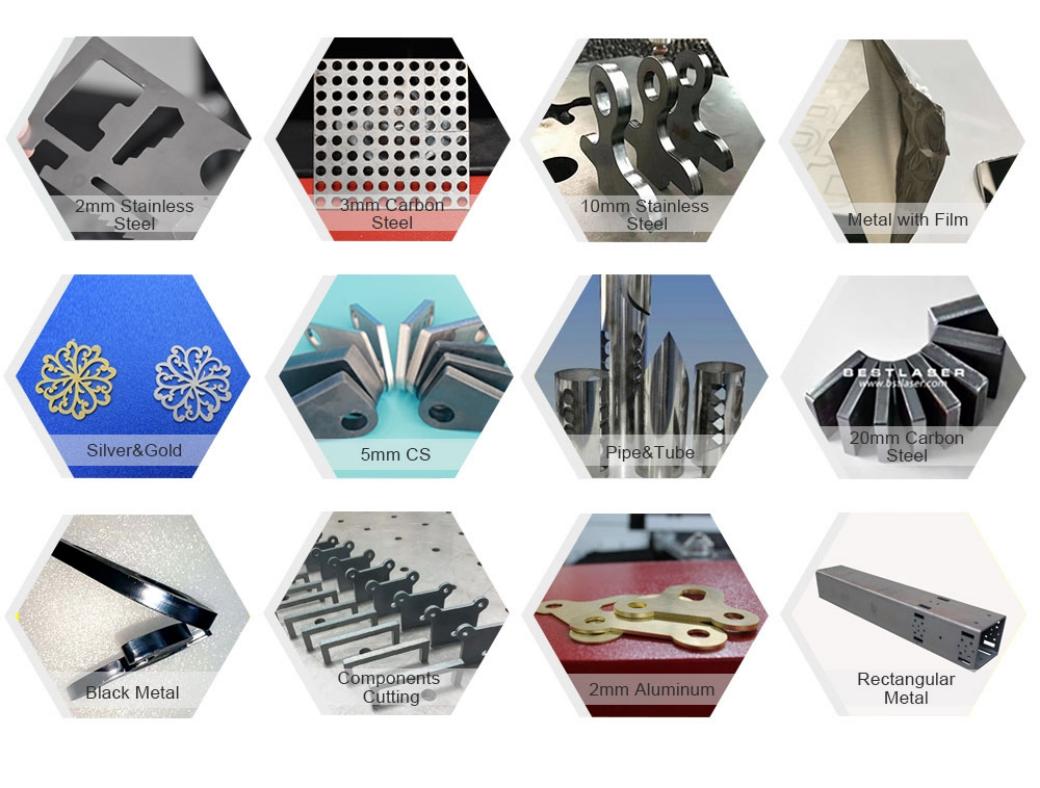

Application

Fiber laser cutting machine is widely applied in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal processing, kitchen processing and other manufacturing and processing industries.

Cutting Materials:

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal sheet cutting.

Optional Items

| Model | BE-FM-3015S |

| Laser Type | Fiber Laser |

| Laser Power | 1000w 1500w 2000w 3000w 4000w 6000w |

| Laser Source | Raycus (Optional: Max/Reci/BWT/IPG) |

| Laser Technology | Germany Technology |

| XYZ Working area | 1500*3000*150mm |

| Optional Size | 4000×1500mm/6000×1500mm/4000×2000mm/6000×2000mm |

| Max. Cutting Speed | 30-50 Meters / Min (up to materials) |

| Max. Location speed | 60m/min |

| Laser wavelength | 1070nm |

| Minimum line width | ≤0.1mm |

| Location precision | ≤±0.05mm |

| Re-location precision | ±0.02mm |

| Max Acceleration | 1.5G |

| Max. moving speed | 100m/min |

| Supporting Format | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc |

| Power demand | 3 PHASE AC 380V 50HZ/60HZ |

| Cooling Way | Water Cooling |

| Worktable max. load | 4000KGS |

| Transmission Method | gantry type double rack servo drive |

| Table-driven system | Japanese Imported Servo Motor & Driving System |

| Focus Method | Following and Automatic Adjust Focus |

| Control Method | Offline Movement Control |

| Control software | Cyprus/NC Studio |

| Size Dimension | 4500mm ×2900mm ×1750mm |

| Working Environment Temperature | 0℃~45℃ |

| Working Environment Humidity | 5%~95% non-condensing |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-FM-3015S | 446cm×223cm×180cm, 179CBM | 4000KG |

|

|

|

| Inside layer is covered by thickening plastic bag and foam for waterproof. | Loading container EXW factory, workers putting machine into container | Send to the named loading port for shipment by sea which needs 20-50 days |

-

SAMEH ABDELWAHAB

★★★★★Post a review on Aug 21, 2022 From Egypt

Very Powerful Machine, we are planning to buy many machines in the future and to be representative for your company in Egypt.

-

Sangho Yi

★★★★★Post a review on Aug 21, 2022 From Korea

The Laser and the motion are very good, excellent cutting effect and we are very satisfied with it, strongly recommend to clients.

-

Salvatore marrapesa

★★★★★Post a review on Aug 21, 2022 From Italy

All problems is solved we may need some help with technical support while testing but everything is working fine now, and the cutting is very good.

-

UAE

★★★★★Post a review on Aug 21, 2022 From Hadhrat Ali

We can assemble and test the machine via your user manual and training video, no need any technical support, check the cutting sheets by me.

-

Miguel A Hernandez

★★★★★Post a review on Aug 21, 2022 From USA

Good company, fast and veary good service. like always great product.

-

Jose Eduardo Paris Muñoz

★★★★★Post a review on Aug 21, 2022 From Brazil

Always good work. with lot of instructions… technical service is very good… I m very happy to ov laser, it’s my 8th machine I have order to them.