Industrial Aluminum Channel Letter Bender for Sale

| Category: | Channel Letter Bending Machine |

| Model No.: | BEL-A200 |

| Views: | 6500 |

| Rating: | ★★★★★5/5 Based on 1000 Votes |

| Price Range: | US$3000 – US$4500/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time: | 7-10 Days |

| Shipping: | Sea/Train/Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

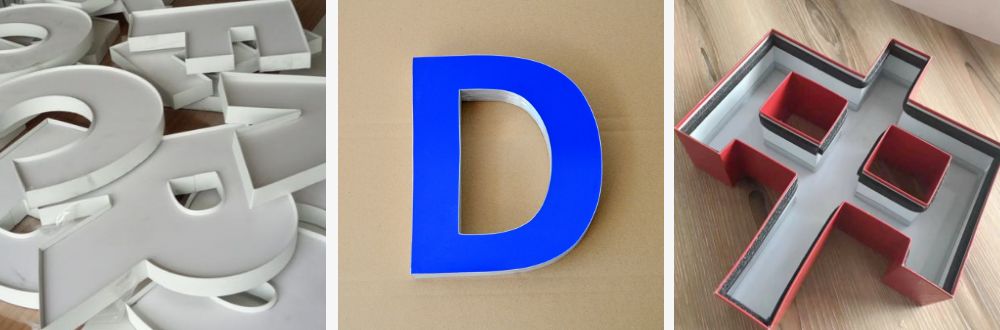

A200 channel letter bending machine is the perfect upgrade of the A130. It can be used to process flat aluminum and folding aluminum with height of 20CM and 1.2MM thickness. It is suitable for most aluminum profiles on the market and can bend 9 cm sponge strip aluminum strips. It is your first choice for high-side aluminum letters.

Machine Feature:

◆ Specially designed for bending various aluminum materials like aluminum strip,fold-edge alumium, aluminum profile, solid aluminum, etc.

◆ Max bending width can be made as 200mm.

◆ Bigger slotting knife which has faster slotting speed +arc bending speed

◆ Two sets three phase step which can make sure strong torque during bending which make sure fine bending effect

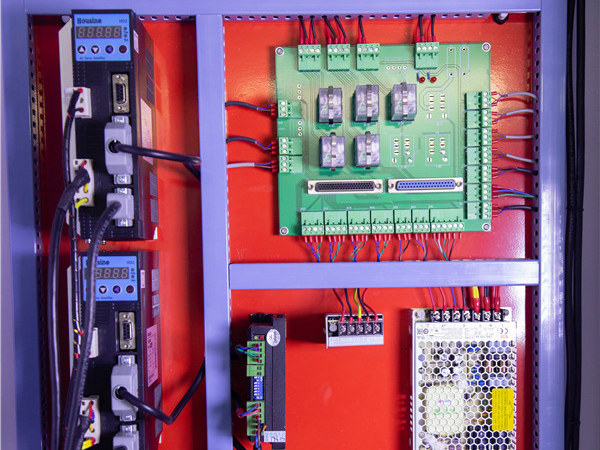

◆ Germany Brand Delixi electronic components, MW power supply

◆ Automatic slotting adjustment

◆ Equipped with protection measures and installed with protection cover around the cutting tools which produced as TUV standard

◆ Exquisite workmanship, Thicken machine cover and elegant design, machine net weight is more than 350kg

Parts Introduction

High Precision Roller Feeding

High precision roller feeding enable the smooth feeding of Aluminum strips, and correct the aluminum’s position.

Electric Slotting Depth Adjustment

For different usage, the slotting depth needs to be different. This machine can adjust the slotting depth in the software. When setting up slotting depth in the software, it can change cutting depth automatically. It brings great convenience, and save labor.

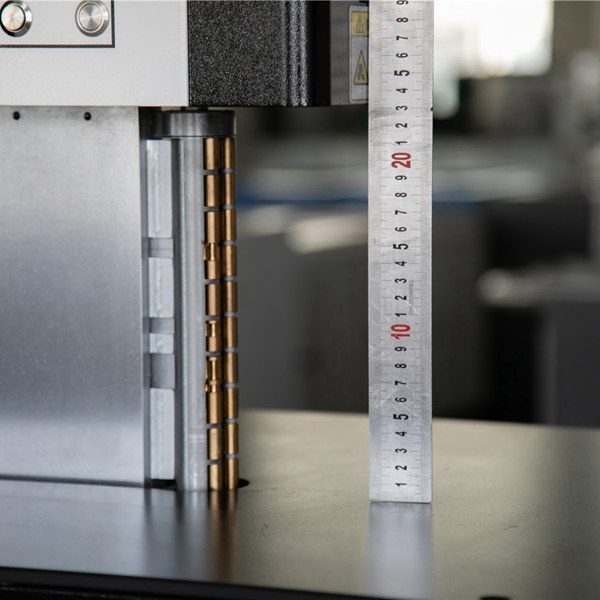

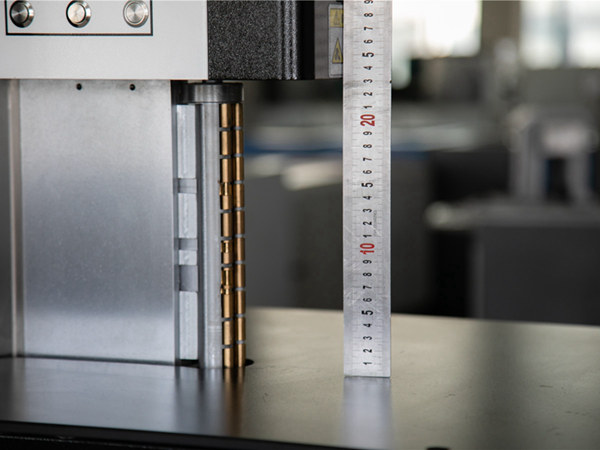

Max bending height 200mm

It is specially designed for big super letters and meet the demand for high-end aluminum letters requirements.

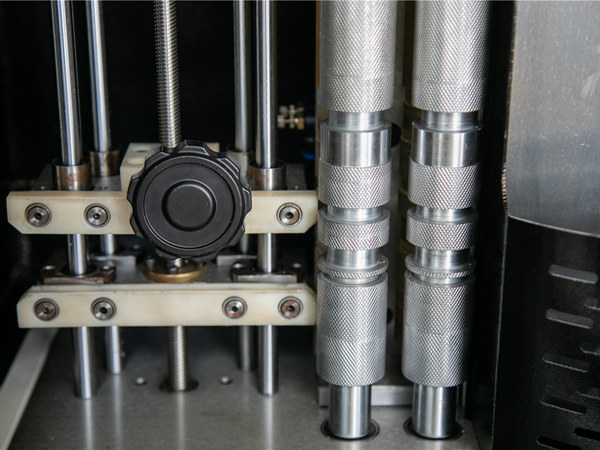

Two-axis linkage fast bending mechanism

The double-axis linkage copper roller shaft arc bender eliminates waiting time in forward and reverse arcing, high efficiency, no scratch on aluminum material, smooth discharge and low resistance.

Standard Wire Layout &I/O Integrated PCB Board

Integrated PCB board, power supply, driver…all assembled in cabinet, which prove our strict production standard and bring convenience to customers

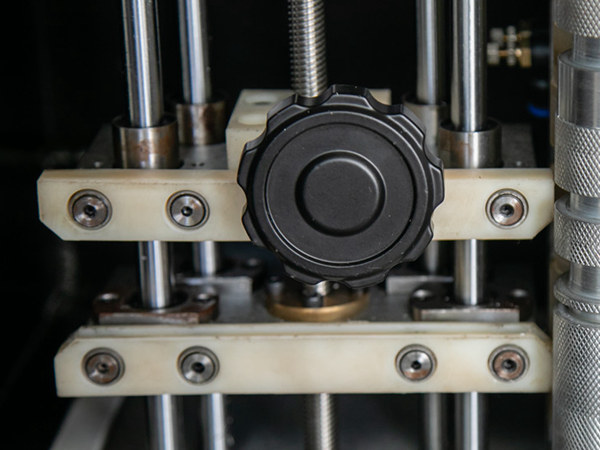

Thread lifting clamping mechanism

Adopt manual-operated thread lifting to lock the clamping material for easy adjustment of material height.

Application

Applicable Industries: Advertising industry (Logos, signs, neon signs, billboards, light boxes production, outdoor advertising and other advertising production).

Applicable Material Width:30-200mm Thickness:0.5-1.2mm Materials: Single-Folded-Edge Aluminum and Double-Folded-Edge Aluminum, all colors Aluminum edgings or 7,9,11cm edgings with sponge.

Optional Items

| Hardware | Feeding system | Rolling continuous feeding structure(Closed loop self-test system) |

| Slotting system | Pneumatic lifting rotary milling cutter structure | |

| Bending system | Two-axis linkage copper shaft roller extrusion system(Non-scratch material) | |

| Motor | Three-phase stepper motor 2 set; Two-phase stepper motor 1 set; DC brushless motor 1 set |

|

| Weight | 200kg | |

| Dimensions | L2150mm×W650mm×H1560mm | |

Performance |

Application Materials | Flat aluminum,edge aluminum,rectangle/triangle aluminum,channelume |

| Bending Height | 20—200mm | |

| Material thickness | 0.5—1.2mm | |

| Support format | AI PLT DXF NC | |

| Feeding accuracy | Length±0.1mm; Radius>10mm | |

Sfotware |

Control card | Four-axis motion control card |

| Software system | Auto drive bending system | |

| Input voltage | 220V 50Hz 3Kw | |

| Air pressure | 0.6-0.8Mpa |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-A200 | 188cm×91cm×177cm, 3.028CBM | 350KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craft case. |

-

Hossein Azimi

★★★★★Post a review on Aug 21, 2022 From UK

The machine is very strongly mechanically and features very good, easy software and performance is very good.

-

Muhammad Tayyab

★★★★★Post a review on Aug 21, 2022 From UK

Very powerful machine, it has brough many potential clients to my business, recommends to others who want to enter sign field.

-

Ermal Alushi

★★★★★Post a review on Aug 21, 2022 From Italy

The trim cap channel letter letter bender machine BEL-A200 is working fine, for now we do not have any technical support.

-

Josef Helmlinger

★★★★★Post a review on Aug 21, 2022 From Chile

The machine works well. I will introduce to friends to buy.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From Spain

Your letter bending machine is very fine and I am so happy and thankful to u and ur company.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From France

Also let you know, we have been using the machine very well, because of pandemic we haven’t been able to us it that much, but in the little we have made really good letters with it!

-

Ernesto Reyes

★★★★★Post a review on Aug 21, 2022 From USA

High quality machine. I want to thank supplier for her support and enormous help during purchase.