Multifunctional 1000W 1500W Automated Laser Welding Machine

| Category | Auto Laser Welding Machine |

| Model No. | BE-W1500D |

| Views | 79600 |

| Rating | ★★★★★4.5/5 Based on 200 Votes |

| Price Range | US$5999-US$15999/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 7-15 Days |

| Shipping | Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

This automated laser welding machine is specialized in traditional hardware, new energy and other industries. It has the advantages of high power peak, good beam quality, thin spot, flexible installation and so on. The laser beam can realize different spot shapes, and can simultaneously process the abnormal spot, so as to meet a variety of high demand welding effects such as hybrid welding, and achieve precise and efficient welding.

Good Features

◆ This automated laser welding machine can apply for different materials with different thicknesses and different coatings, could be welded into one integral plate, which greatly improves the applicable range of welding.

◆ The heat dissipation is good, and the huge refrigeration system is not required. Conversion efficiency, low threshold, good beam quality, and narrow line width.

◆ Continuous laser fiber optic welding machine adopts integrated structure, which can protect the operation safety and environment, and can work normally under various conditions.

◆ Compact structure, the automated laser welding machine overall size is much smaller than the traditional YAG laser system, so the movement is very flexible.

◆ Small size, long life and easy system integration. The fiber optic welding machine can operate normally under the harsh environment of high temperature, high pressure, high vibration.

◆ This equipment is mainly for butt-sealing welding of pipes, which makes up for the trouble of traditional argon arc welding technology for thin plate welding with large heat fusion, easy deformation and post-processing.

◆ Optional rotating fixture, suitable for spin welding

◆ The laser can set continuous light output and modulated light output mode, configure coaxial air output, and optional side blowing.

◆ No special maintenance is required, and no frequent dimming is required compared to the YAG type.

◆ Operators can learn to operate quickly, saving you expensive technical labor costs!

◆ The heat affected zone is small, and the deformation caused by heat conduction is also the lowest;

◆ Worker efficiency is high, and long-term welding is not easy to fatigue.

◆ Traditional welding adopts arc welding and other methods, which has low work efficiency and easy fatigue. This product breaks through traditional methods and adopts directional point-to-point welding, which is 10-15 times faster than ordinary welding and has high work efficiency.

Parts Introduction

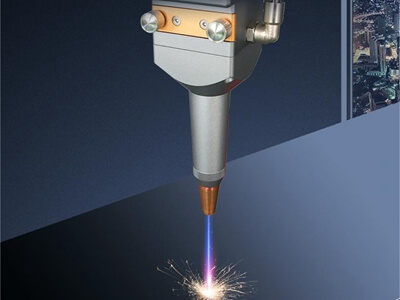

Fiber Laser Source(1000W, 1500W, 2000W)

- The automated fiber laser welding machine adopts fiber laser source, the beam quality is good, and the welding spot is extremely fine.

- With the optical fiber as the wave guide medium, the coupling efficiency is high. Lifespan over 10 years, without consumables and free of maintenance.

Welding Head

- Fiber laser head can rotate left and right flexibly.

- Flexible operation, the fiber welding machine is easy to be integrated in multi-axis robot and galvanometer system.

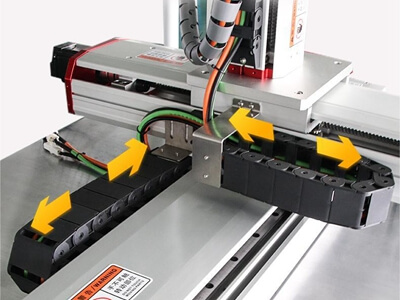

Automatic XY Moving Table

- It adopts Japanese servo motors, and enables to move on left/right/front/back, which is very convenient for big work pieces welding.

- High precision positioning and fast response.

Industrial Water Cooling System

- Industrial water chiller can cool the machine and make the machine work in good condition.

- Operators can adjust the temperature parameters on the chiller panel. The water chiller comes with air-conditioner system.

CCD Display Screen

- It can reflects the welding details intuitively which can not be discovered by human eyes.

- Convenient adjustment for light spot size and position of solder joint.

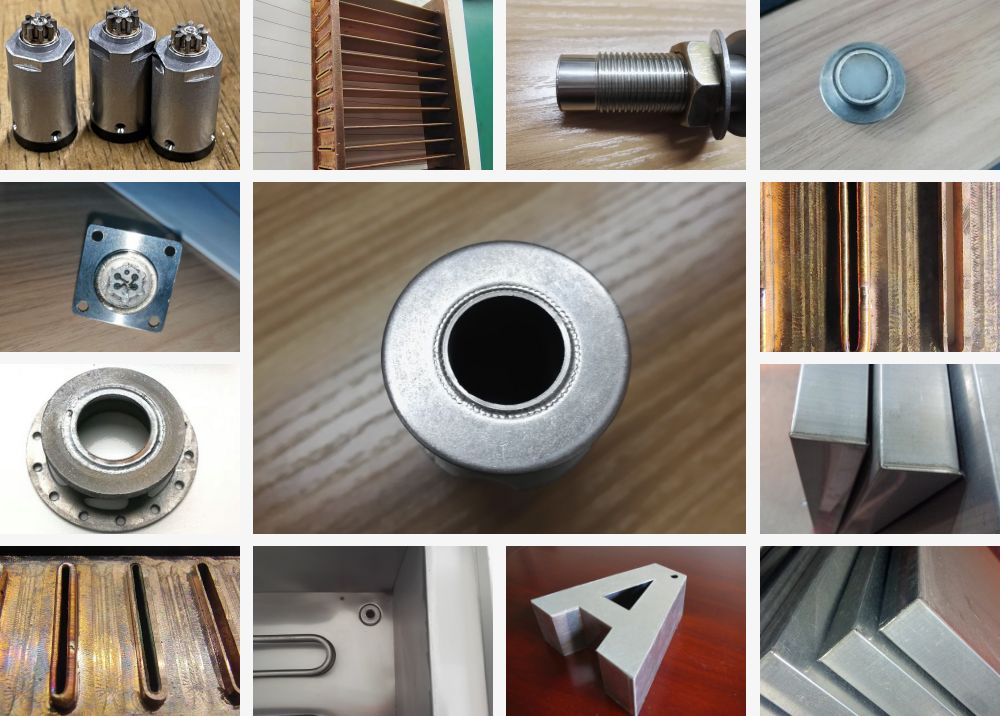

Application

It is applicable to the welding of optical communication devices, metal connectors of smart watches, manual accessories (middle plates, nuts), batteries, optical fiber coupling devices, kinescope electron guns, connectors, microelectronic components, medical devices, precision parts, etc. It is mainly used for continuous welding, cutting and punching of various metal plates (copper, aluminum, titanium, stainless steel, low carbon steel, etc.); Or some non-metallic materials such as ceramics and silicon wafers.

| Product Name | Fiber Optic Welding Machine |

| input Voltage | 220V/50hz/1ph |

| Fiber Laser | Continuous Fiber |

| Laser Wavelength | 1064 nm |

| Peak Output Power | 100W-2000W adjustable |

| Focused spot diameter | 0.2-3 mm |

| X-axis and Y-axis travel | X*Y=300 mm*300 mm |

| Platform size | X*Y=400 mm*400 mm |

| Moving speed range | 0-50mm/s |

| Reset accuracy | 0.03mm |

| positioning accuracy | Less than 0.025mm |

| Z axis | Electric lifting height 200 mm |

| Rotary fixture (optional) | The rotating fixture with diameter of 100mm can be manually adjusted with angle of 0-90_. It can be locked at any position in the fixture. It is driven by stepping motor. The stepping equivalent is 0.01 degree, the positioning accuracy is 0.1 degree, and the repetitive positioning accuracy is 0.05 degree. |

| Display mode | Observation of Coaxial CCD LCD Screen |

| Location mode | Red light |

| Luminous mode | automatic |

| refrigeration system | Overtemperature alarm, flow protection water level protection. |

| Control system | Industrial Computer CNC2000 Control Software |

| Continuous WorKing Table | ≥24h |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W1500D | 1.85m×0.7m×1.75m,2.26CBM | 500KG |

| Item No. | Name | Description | Brand | Qty. |

| 1 | Laser Device | RFL-C1500 (Raycus) | Raycus | 1SET |

| 2 | Welding Head | Industrial Grade | Raytools | 1SET |

| 3 | Controller | CNC2000 | WUHAN HGTECH | 1set |

| 4 | PC | Industrial PC, with well installed software and parameters | Top China Brand | 1SET |

| 5 | Working Table | Automatic,300*300mm | Panasonic servo | 2SET |

| 6 | CCD | 8 inch coaxial LCD | Shenzhen | 1 SET |

| 7 | Water Chiller | 1P industrial refrigeration system | DOLUYO | 1SET |

| 8 | Package | Compound Wooden Cases | BST LASER | 1 SET |

| 9 | Spare Parts | Installation Tools,5 PCS Protection Lens,10PCS Welding Nozzles ,Cables,etc | BST LASER | 1 SET |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

talleresvisocar limens

★★★★★Post a review on Aug 21, 2022 From Spain

The welding is very smooth, and very easy to use. With professional technical guidance, we get started quickly. In the past, it took 1 day to finish the job, but now only half day, which greatly improved the production efficiency.

-

Clinton Mills

★★★★★Post a review on Aug 21, 2022 From South Africa

Welding quality is good, and the welding effect is satisfactory. It is easy to operate, and the design is very user-friendly, all five stars!

-

Walex Chacon

★★★★★Post a review on Aug 21, 2022 From US

Perfect machine! The logistics is also fast, it is worth buying! !

-

Erivaldo Brito

★★★★★Post a review on Aug 21, 2022 From Brazil

Good quality, easy to operate, cost-effective, super!

-

Andrey Maier

★★★★★Post a review on Aug 21, 2022 From Romania

After comparing some companies, we chose BST. It is cost-effective, good quality and economic price.